Yesterday, Dafeng railroad gained a historic breakthrough, high-speed rail equipment to achieve the first independent export.

With the last seat of the package, Dafeng Railway developed India's high-speed rail seat officially off the line, will embark on a journey to India, marking the first time Dafeng Railway completed the independent export of high-speed rail equipment, but also the company from the underground to high-speed rail development of industrial upgrading, but also opened a new chapter to expand the overseas market.

In order to achieve outstanding quality, the company set up a professional project team, and in just 4 months, more than 1,000 parts of the high-speed rail seat from research and development, design, delivery samples to full production and assembly completed.

First-class and second-class physical map

The innovative design of the high-speed rail seat is divided into first-class and second-class seats, designed strictly according to the passenger compartment seat standard of the moving train. The total height of the seat is 1040mm, with 180°rotation, backrest flip, folding footrest, folding small table, etc. The seat is spacious and comfortable, and the backrest frame is made of high-strength aluminum alloy. The seat is spacious and comfortable, the backrest frame is made of high-strength aluminum alloy light material, the seat cover is made of high-strength printed cloth, fire protection meets DIN5510-2 requirements, the front and rear are each equipped with a charging socket, the middle armrest is equipped with a headset component to enhance the riding experience.

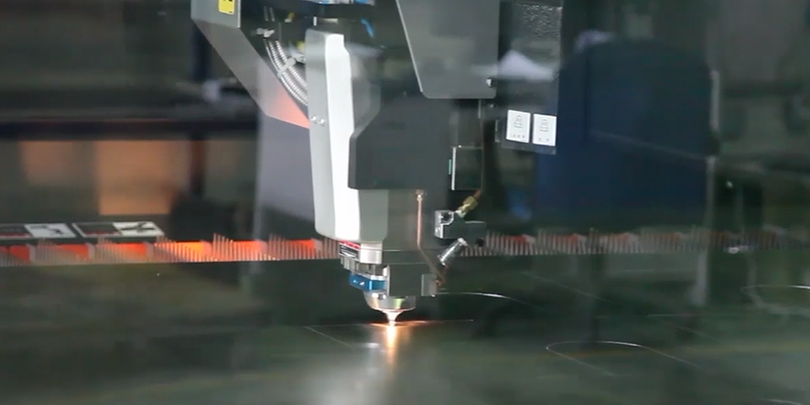

Laser engraving machine in operation

In recent years, along with the rapid development of the rail transit industry, Zhejiang Dafeng Rail Transit Equipment Co., Ltd. as a wholly owned subsidiary of Dafeng Industry, relying on the brand effect of Dafeng, specializing in the research and development, production, sales and service of rail vehicles as a whole interior and seats, has obtained the international IRIS, EN15085, DIN6701 system certification, and has established a partnership with Changchu, Sifang, Puzhen, Zhuodian and other OEMs. In recent years, the company has undertaken and delivered interiors and seats for Ningbo Line 2, Hangzhou Line 2, Guangzhou Line 7, 8, 14, 21, Shenzhen Line 2 and 5, Wuhan Line 4 and 6, Kunming Line 3, Urumqi Line 1, Rio Line 4 in Brazil, Line A in Argentina and Shiraz Metro in Iran, as well as intercity seats for Changsha Maglev and Changchik intercity trains.

In the face of fierce competition, Dafeng Railway Traffic does not forget its original intention, adheres to the industry, develops the enterprise by science and technology, upgrades the industry, sets up an independent design and research institute, learns the advanced business philosophy, transforms the scientific research results one after another, and actively enters the overseas market. Dafeng Railway Traffic actively to create a leading rail transit high-end equipment suppliers, will have a more brilliant, brilliant tomorrow.

Related news

News classification

Hot news

×